Why Skills Matter for Cummins Diesel Engine Repair

Even the simplest Cummins diesel engines will be difficult to maintain. The engines have a good reputation for being robust and dependable, with a long service life worldwide, and can be used in a broad range of applications, including long-haul trucks, construction, and even boat engines. Nevertheless, like any other complex engine, these engines require years of experience to operate effectively in the event of a problem. The skills needed for Cummins diesel engine repair are undoubtedly beneficial to mechanics and operators, given the complex structure and high demand associated with it.

Without technicians to maintain them, simple problems can become expensive failures that impede productivity and compromise safety. This article examines why skills are crucial for Cummins diesel engine repair, what distinguishes these engines, and the significant value of service personnel in making the entire process easier.

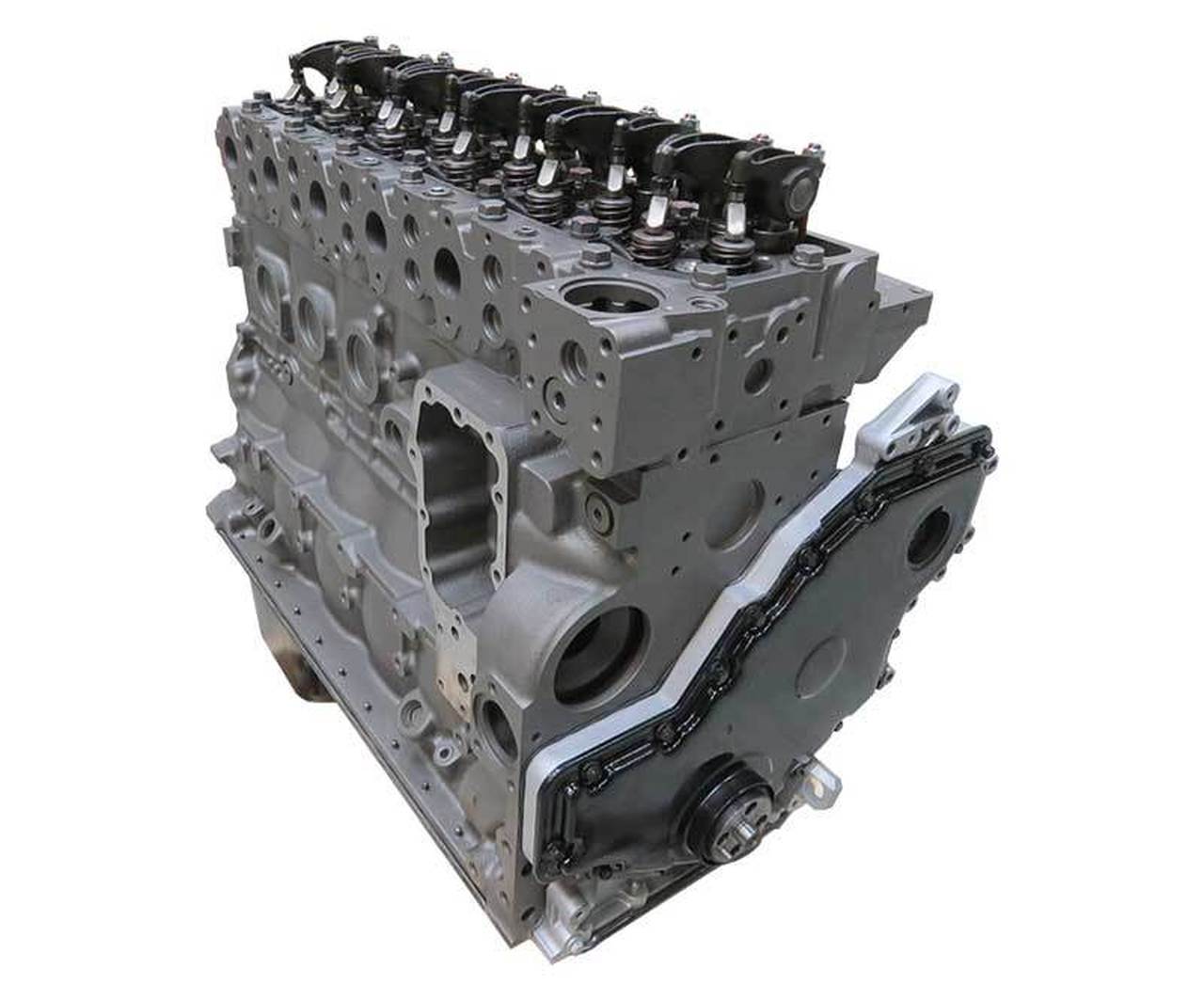

The Complexity of Cummins Diesel Engines

The Cummins diesel engines can be distinguished by outstanding engineering. They have their engines, turbochargers, and emission control system models that are designed to be high-performance even in extreme conditions. These engines are designed to deliver both power and fuel efficiency while upholding high environmental standards. This implies that they are also introducing new technologies, namely, electronic control modules (ECM), high-pressure fuel injection systems, and aftertreatment systems.

The Cummins engine is a highly complex engine that can be difficult to troubleshoot. A technician needs to understand engine internals, their interplay, and repair processes. The absence of such knowledge can lead to either a misdiagnosis of one of the parts, replacement, or even additional damage.

Why Skills Are Essential in Diesel Engine Repair

Diesel engines work differently from gas-powered engines. Diesel technology operates at higher compression ratios, with various injection and operational conditions under harsher conditions. Skills are essential in this case because what is demanded isn’t just book learning but also practical experience to diagnose and fix the problem correctly.

An experienced technician is capable of:

- Interpret error codes and engine diagnostics.

- Locate problems with special tools and programs.

- Remove tough pieces and reassemble them without compromising performance.

- Repaired systems are thoroughly tested to ensure they function correctly.

Such abilities are even more critical in Cummins engines, where the electronic controls and the emission system are very much intermeshed. Errors do not only result in mechanical failures but also compliance breaches, increased fuel usage, or engine failures.

The Cost of Inexperience

The expenses of inexperience are one of the most apparent reasons why skills are needed. It may be cheaper to employ an incompetent or inadequately trained mechanic in the short run, but the overall cost in the long run can be very high. For example, a fault in the fuel system may be incorrectly diagnosed, and injectors may be replaced when the actual fault lies in the ECM. Similarly, when reassembly is improperly torqued, it may lead to leaks, cracks, or catastrophic failures.

Besides financial costs, a lack of experience may lead to time wastage. In companies that operate equipment powered by Cummins engines, each hour of equipment downtime results in lost revenue. A well-trained technician can mitigate this risk by promptly detecting and resolving the issue, thereby restoring equipment functionality.

The Role of Training in Building Skills

Skills are not innate; instead, they are developed through training and experience. The Cummins engines are exclusive in terms of line and technology; special training is required. It is also done by manufacturers, who create elaborate service manuals, diagnostic programs, and training courses to enable technicians to master the complexities of their engines.

The trained technicians are not only taught the mechanical aspects of repair work, but they also possess knowledge about the new technologies emerging within the company as Cummins continues to grow. This innovation involves producing engines with reduced emissions, increased efficiency, and improved electronic systems. Consequently, the necessity of constant education gains even greater value.

Why You Should Trust Cummins-Trained Techs

The primary factor in the discussion is the need to select technicians who are specifically trained on the Cummins engines. Cummins-trained techs are the most skilled in servicing these engines. They are specially trained according to Cummins’ requirements, enabling them to be conversant with the engine design, diagnostic tools, and approved repair methods.

These professionals are selected to ensure that the owners are assured that the repairs will not only restore the engine’s performance but also protect the integrity of the warranty and adhere to the warranty and compatibility terms and conditions of the engine. They are also capable of performing simple repairs and the most complex overhauls, doing it efficiently and accurately.

Benefits of Skilled Technicians for Cummins Repair

There are benefits to having skilled technicians when dealing with the Cummins diesel engines.

To begin with, they provide accuracy in diagnosis. Through diagnostic software and by applying their training, they can identify problems without wasting time on trial and error. This is time and money saved.

Second, trained technicians save the lives of the engines. Changing the engine and performing proper repairs, doing the torquing correctly, and adhering to service standards ensure that the engine will continue to perform at high efficiency. Wrong maintenance, on the contrary, may reduce the life of the engine to a minimum.

Third, they improve safety. Any malfunction of a diesel engine can be hazardous, whether it is the explosion of a gasket under pressure or the leakage of fuel. Repairs with skilled labor minimize risks, which in turn safeguard operators and property.

Lastly, qualified technicians give peace of mind. Proprietors can be assured that the engine will perform efficiently, emissions will comply with stipulated laws, and the occurrence of unforeseen failures will be minimal.

Conclusion

Cummins diesel engines are a testament to excellent engineering, and their high standards of repair and maintenance ensure reliability. Skills are mandatory in this area. As it involves knowledge of complex fuel systems to meet emissions standards, the role of trained technicians in ensuring that the diesel engine is fixed correctly is key to success.

Ineffective work results in expensive errors, time wastage, and safety issues; practical training ensures the correctness, effectiveness, and stability of the engine. Skilled personnel can be hired, particularly Cummins-trained personnel, thereby ensuring that the owners are in a position to invest, minimize downtime, and perform optimally.

With Cummins still being innovative, the cost of skills is bound to increase. The future of diesel engine repair lies with individuals who welcome learning and adapting to new technologies, as well as those who are always willing to provide the best. Skills are essential, as they are what can be considered the difference between an engine that is just running and one that is running at its optimum level.